Continued...

Day 1 - Friday Morning Session- Extreme Prep Wash

The Extreme Prep Wash is NOT simply washing a car. It's where you do ALL the things possible to get the car clean WHILE the car is wet. This is called Wet Work. It includes,

- Topical Glass Polishing

- Headlight Correction

- Wet Wash Engine Detailing

- Machine Scrubbing Tires and Cleaning Wheels

- Full Contact Body Wash

- Mechanical Decontamination

- Final Rinse and Dry

Here's our Training Car. This is a 2000 Honda CRV and according to most car club rules, this qualifies for

Antique Status. The primary teaching goal for this SUV is to teach how to do a proper extreme prep wash.

Aged, Oxidized, Yellowed Headlights.

The problem and risk for trying to machine sand using a rotary polisher

Most rotary backing plates tend to be hard. Even flexible backing plates are still fairly stiff, especially at the face of the backing plate. The problem is, if you attach a 3" sanding disk like a Mirka Abralon 500 Grit Sanding Disc, on the face of a hard backing plate, if you TILT the polisher, even a little bit, you risk having the sanding disc cut a DEEPER GOUGE into the plastic. The only way to recover from this is to hand block sand the headlight until you've leveled the outer surface of the headlight to the lowest depth of the gouge. Been there done that when a past student challenged me on my claim. I'm the guy that hand block wet sanding the headlight to remove the gouge.

Fast-forward a few years and before this class, I'm thinking...

how can I make machine sanding with a rotary safe?

Then it came to me, by adding 2-3 foam interface pads to the backing plate first, there will be PLENTY of CUSHION, which will allow and enable the face of the sanding disc to stay flat against the surface in case anyone accidently holds the polisher in a way to put more force on the EDGE of the sanding disc, instead of holding it flat.

It worked.

So after this January 2024 detailing class, moving forward I teach everyone how to machine sand headlights using a rotary polisher.

Why?

Because it's FASTER. All of the other options for machine sanding headlights include using free spinning, random orbital polishers, being used as sanders. The problem with this is called Sanding Disc Stalling. That is, in the same way that a spinning buffing pad will stall out and simply vibrate against the paint when using a free spinning, random orbital polisher to buff paint, this also happens when trying to use these types of tools to machine sand headlights. In other words, it will take LONGER to machine sand neglected headlights as well as take more effort and techniique. Using a rotary simply eliminates sanding disc stalling because as you all know, a rotary polisher is a GEAR-DRIVEN tool. All this stuff also applies to why I show gear-driven orbitals for machine sanding gelcoat, instead of free spinning sanders and polishes to sand gelcoat. With a gear-driven orbital, like the FLEX XC 3401 VRG aka the BEAST - there's simply NO sanding disc stalling.

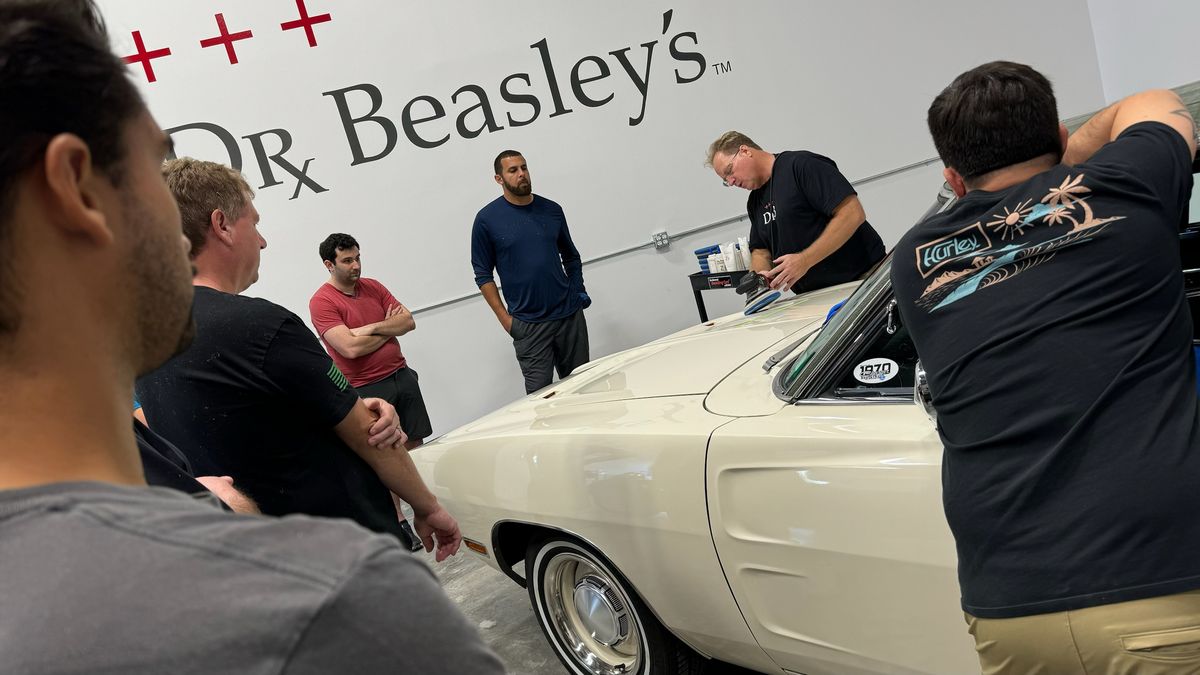

Here I'm showing everything I explained above to the class, so they know not just what to do, but WHY they're doing it.

Then a quick demon on how to use this tool for machine sanding headlights. Note, you don't really need the extension and it would be easier to use the rotary without the extension. I have extensions on some of the rotary polishers for moving the body of the tool away from the tire when machine scrubbing tires like you see

HERE.

Next I turn the students loose!

I also have a FLEX PXE-80 cordless polisher, with a 6mm drive unit, so the students can see and understand what I mean by sanding disc stalling. When used with the 3mm, 6mm or 12mm drive units, the FLEX PXE-80 is a free spinning, random orbital polisher and thus will stall out when buffing paint or sanding headlights. It can still be done, it just takes longer as well as more thinking and technique.

See the two foam interface pads between the backing plate and teh sanding disc? That's the secret to make using a rotary polisher SAFE for sanding headlights.

Here's the results after the students took turns learning to machine sand headlights using 500, 1000, 2000 and finally 3000 grit sanding discs. By the time you finish out with 3000 grit, the plastic starts to become clear again as the sanding marks are so shallow and refined. This also makes it faster and easier to buff out later when we move the car into the garage for detailing.

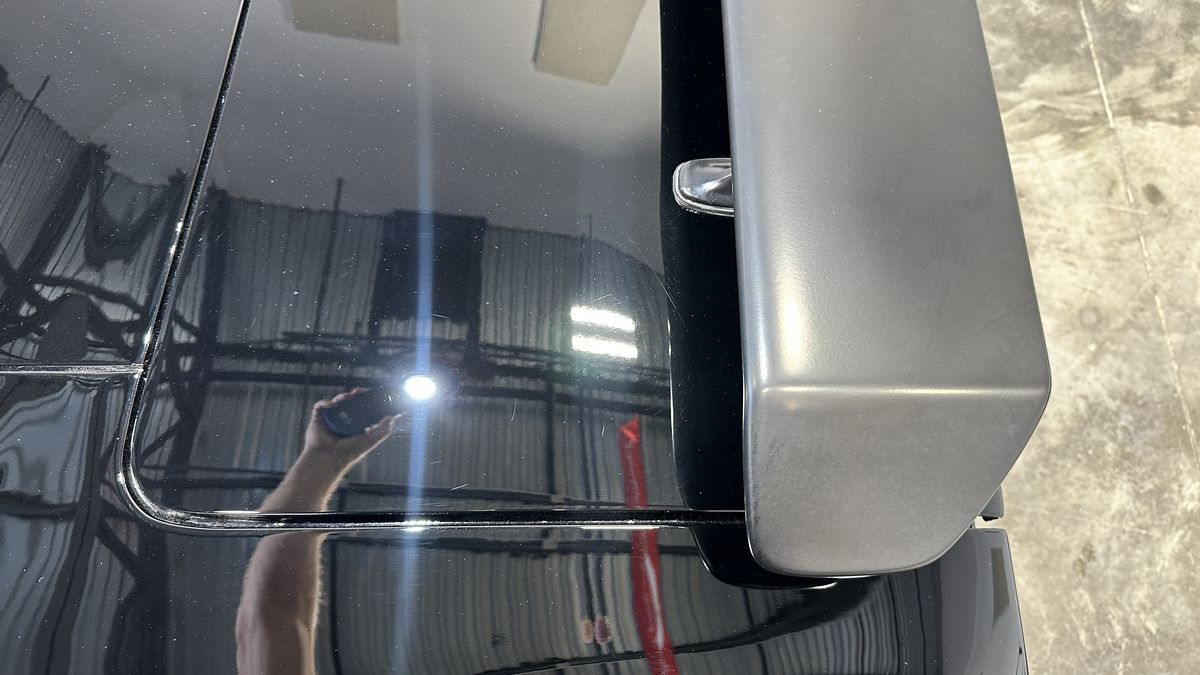

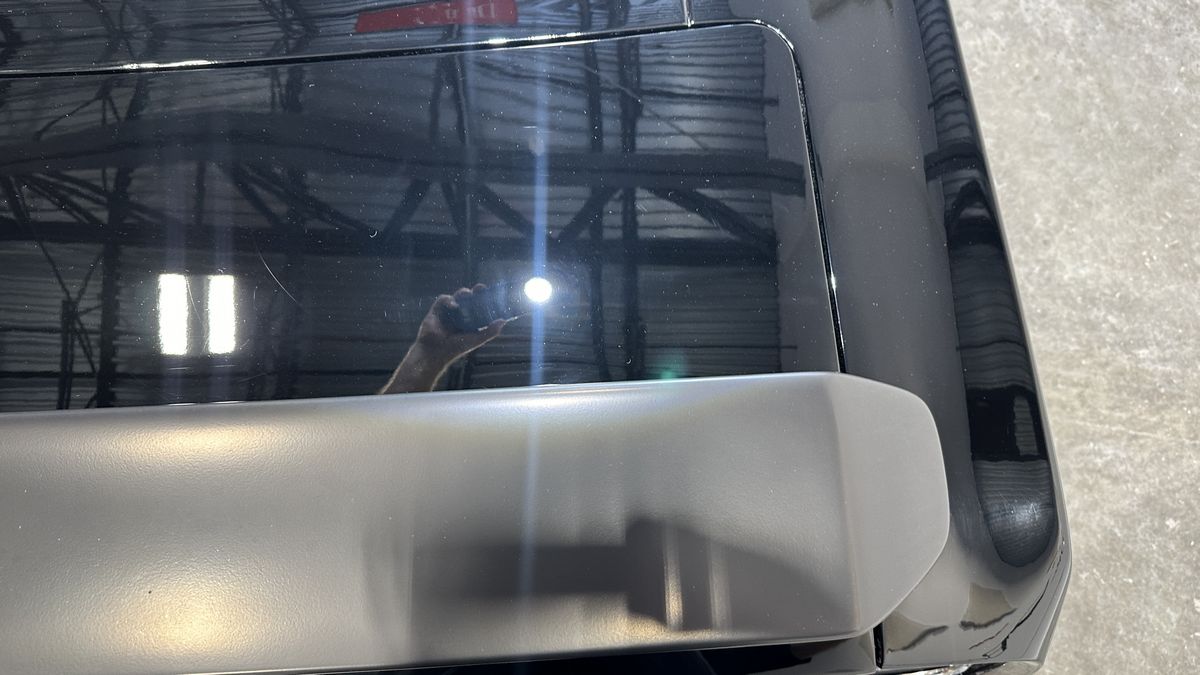

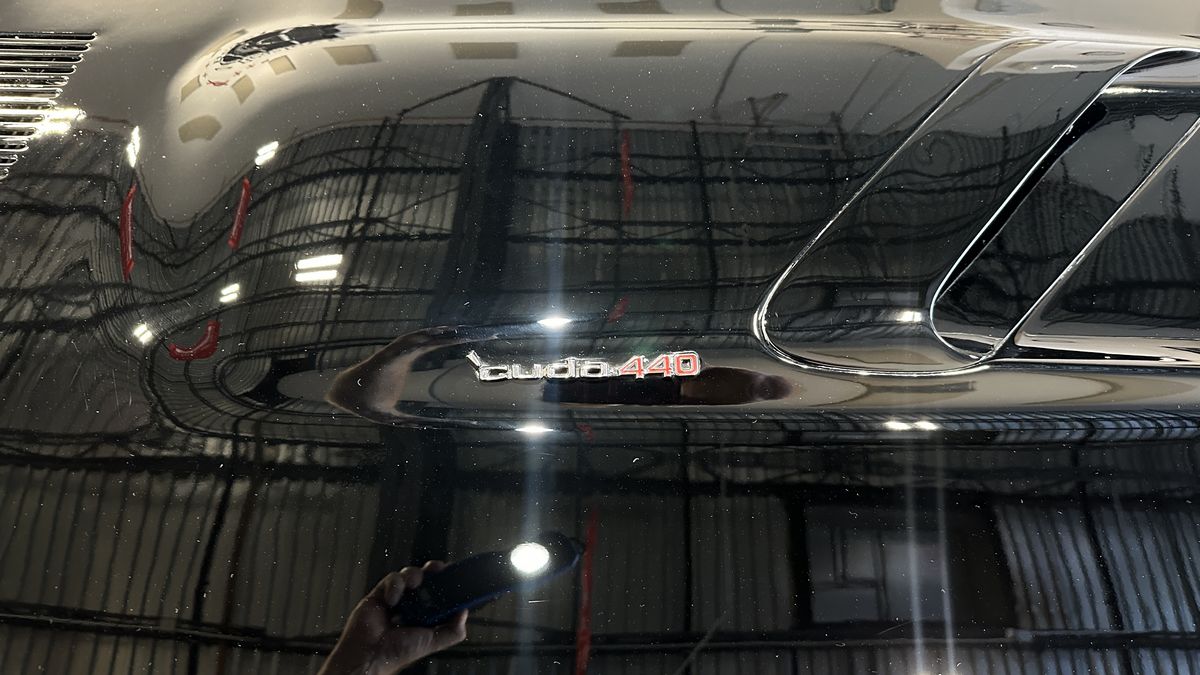

Topical Glass Polishing

All daily drivers suffer from water spots, drizzle stains and traffic film or road grime, building-up on exterior glass. You could buff the class later after washing the car, but I teach to do this BEFORE washing the car and then when you do wash the car you will automatically wash any polish splatter from around the window frame and adjacent body panels. This saves time and steps.

Wet Wash Engine Detail

While not horrible looking, my guess is this engine and engine compartment have never been properly cleaned and detailed.

First step for a Wet Wash Engine Detail is to blow-out all the leaves, pine needles, sticks, bugs and loose dirt via compressed air.

Next, you wash the underside of the hood.

There was some super stubborn oily dirt on the passenger side of the hood and another great way to use a 5" rotary brush on a rotary polisher to do all the hard work for you.

Next rinse thoroughly

You clean the underneath of the hood FIRST and then it doesn't matter if there's any grime that lands on the engine because next - you're going to clean the engine. This is called, working smarter instead of harder.

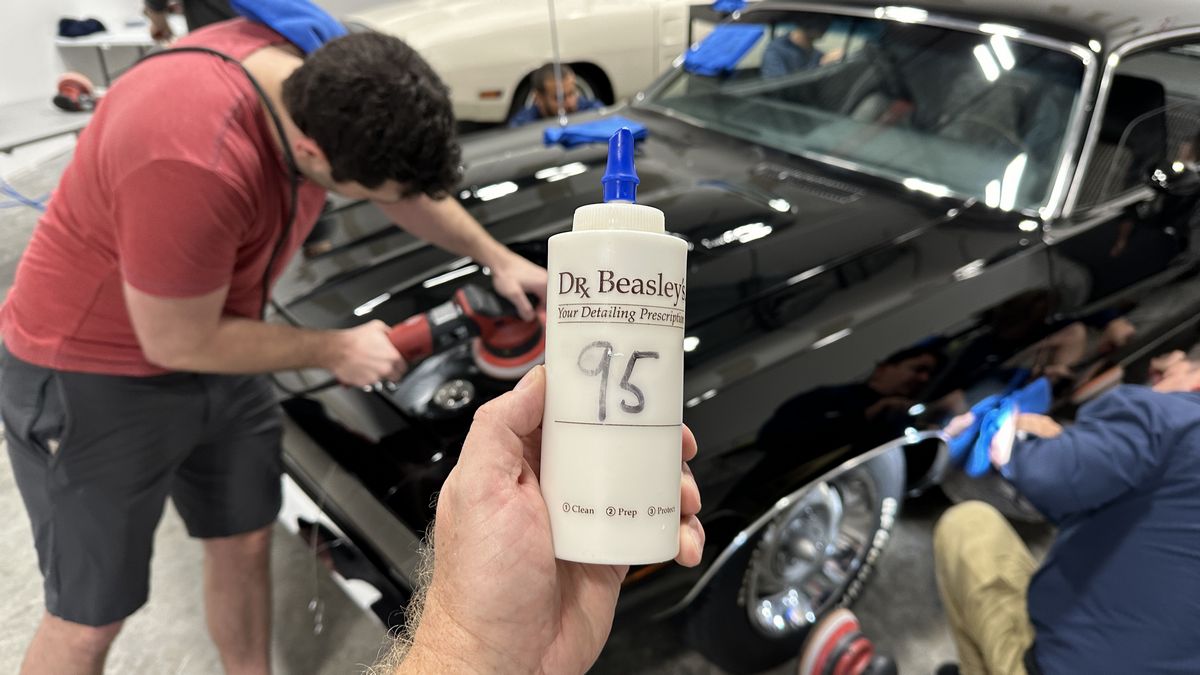

Next up - spray the engine and engine compartment with the Dr. Beasley's Premium Degreaser.

Clean and agitate the degreaser with a variety of brushes.

This is actually a

Wheel Cleaning Brush you can get at Dr. Beasley's website, and not only does it work great for cleaning rims it works great for cleaning engine compartment.

Then rinse thoroughly and blow-out any standing water.

Clean enough to eat off of.

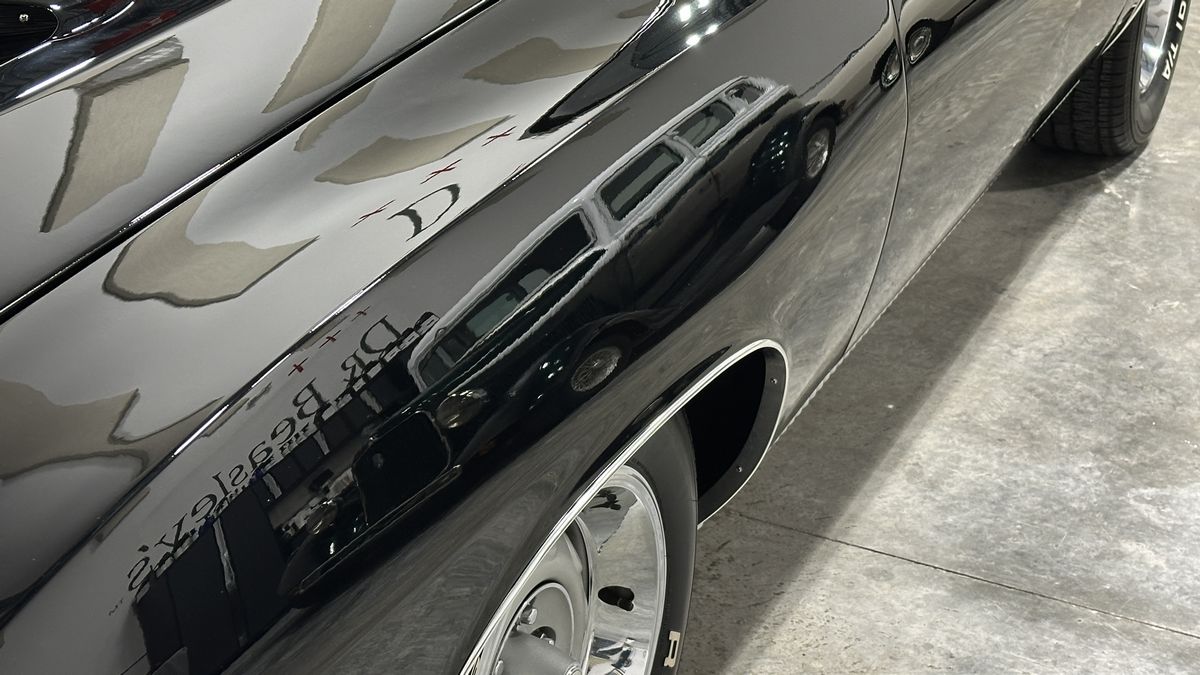

Machine Scrubbing Tires

Working by hand is also an option, but if you own a cordless rotary polisher, (no risk of electrical shock), then let this tool do all the hard work for you.

A lot of cars have faded, neglected plastic bumper covers and body cladding and just like tires, you can scrub these items by hand or let the rotary do all the work.

Mike